Classification

Four batteries of lime kilns were built in the environs of Bugsworth Basin at the terminus of the Peak Forest Canal, namely:

Hence, a total of 19 kilns were built around the basin but they were not all built at the same time nor were they all operational at the same time.

Map 1 shows the location of the four batteries of kilns at Bugsworth Basin.

Map 1.

This page is concerned with the New Road (or Top) Kilns only.

Prior to 1794, when work on constructing the Peak Forest Canal commenced, the valley bottom road to Bugsworth from Chapel-en-le-Frith, to the east, through Chapel Milton and Whitehough, followed the course of the Black Brook (sometimes known as Blake Brook or Milton Water). At Bugsworth an ancient road bridge crossed the Black Brook and on the west side of this it forked. One turning took the road up the valley side to join the upper road from Chinley while the other turning was the ancient packhorse road from Macclesfield and Whaley Bridge over Silk Hill. The site of this bridge is on the north side of the Upper Basin by the terminus of the Peak Forest Canal. The valley bottom road from Chapel-en-le-Frith was liable to flooding at certain times of the year but in contrast to this, the upper road from Chinley was above the flood plain of the Black Brook and hence it provided a line of habitation as well as being a more reliable route for travellers.

A short distance to the west of this bridge two early lime kilns had been built, which acted as a focal point for traders. Here, it is likely that farm produce and general goods were exchanged for burnt lime (quicklime, lime, calcium oxide, CaO). At this time, farmers would have mainly used burnt lime as a soil conditioner but, no doubt, some would have been used to make mortar for building purposes. Limestone was brought to the kilns from a quarry to the east while coal was mined locally. The location of this quarry is unrecorded, nor is it known how limestone was transported from it. However, there is a probability that the limestone was quarried at Loads Knowl at the top of Barmoor Clough and, considering the poor condition of roads in those days; it is likely that packhorses were used to transport it to Bugsworth.

On account of their proximity to the Navigation Inn, these two kilns (later three in number) became known as the Navigation Kilns. It is known that the two original kilns at Bugsworth predated the construction of the canal but their date of construction is uncertain.

With the arrival of the canal, the ancient bridge at Bugsworth was demolished and the meandering course of the Black Brook was diverted along a new and straighter channel. This river diversion commenced just to the east of Bugsworth and it was cut in an easterly direction to rejoin the river close by the Wharfinger's house and office at the entrance to the basin. The easternmost section of this channel was cut through gritstone bedrock and a weir was incorporated into this to provide water to power the nearby Bugsworth Mill. Afterwards, parts of the original course of the Black Brook were reclaimed and used to form the Middle and Upper Basins, the latter being the terminal basin known as Bugsworth Wharf.

The land through which the river diversion was cut was known as the 'Pingot' and several fields belonging thereto were known as 'The Garden'. In the 1790s, the local squire and landowner hereabouts was James Carrington. The Nearer Pingot lay to the north of the original course of the Black Brook and the Far Pingot lay to the south. The Nearer Pingot refers to land upon which the Middle Basin Arm (known as Mr Satterfield's Branch) and associated lime shed were subsequently built to serve the New Road Kilns (see below) and it also encompassed the site of the Navigation Kilns.

The lie of the land immediately north of the diversion was eminently suitable for the construction of lime kilns as it rose steeply above the channel. Modern kilns of the day required the land to be high at the back, to facilitate them being charged with limestone and coal, and low at the front, to facilitate the removal of burnt lime and ash. Accordingly, over a period of several years, eight kilns were built on this land.

In 1808 the Canal Company purchased land in the Nearer Pingot, where the Middle Basin Arm and lime shed were later constructed, and it is likely that work on building the first three kilns commenced around this time.

An early, and significant, reference to these kilns is to be found in the Minute Book of the Peak Forest Canal Company:

18 Mar 1811, Minute 2

Resolved that the 3 Limekilns at Bugsworth now occupied by Highams (who are to deliver up the same in about a month from this time) be let to Wm. Hassall and Jos. Satterfield for one year from the time of Highams delivering them up, at the rent of £100 to be paid on 1 May 1812. Provided that in the case Hassall and Satterfield do in the course of the year build 2 Limekilns of their own as sufficient dimensions to burn the same quantity of Lime as the said 3 Kilns, the Rent shall be 30 guineas only, and that in case Hassall and Satterfield do raise the Upper part of the said Kilns 3 feet above the present height they be allowed the sum of £20 out of the Rent towards the expense of so raising the Kilns and that the Canal Company will allow them to get stone in the Company Quarry for that purpose. Provided also that Hassall and Satterfield do deliver up the Limekilns at the expiration of the year in good working condition. And that in case the Lime produced from the said kilns shall not upon an Average amount to 6 Boat Loads per week the Canal Company shall be at liberty to determine the Agreement on giving one month's notice upon the expiration of which the Kilns shall be delivered up to the Company in good working condition and proportionate part of the Rent paid up to the time of such quitting, And Resolved, that the Clerks do prepare an Agreement for carrying this Resolution into effect.

At this distance in time from these events it is difficult to interpret precisely this Minute. It is likely that the three kilns referred to were the first to be built of the New Road battery. At this time they were being worked by Messrs Highams but in Apr 1811 they were to quit, following which they were to be let to Messrs William Hassall and Joseph Satterfield for one year at a rent of £100 to be paid on the 1 May 1812. Plainly, the Canal Company was using a 'carrot and stick' approach in its dealings with Messrs Hassall and Satterfield. The 'carrot' was that the £100 rent was to be reduced to 30 guineas (£31 10s 0d) if, during the course of 1811-12, they built two additional kilns of their own of sufficient dimensions to provide the same quantity of lime as the original three kilns. Thus the Canal Company was offering an inducement to Hassall and Satterfield to build two additional kilns that were more efficient and would double the output of burnt lime. An additional inducement was the offer of an additional deduction of £20 in the rent if they increased the height of the existing kilns by three feet, the gritstone for this to be obtained from the Canal Company gritstone quarry, that is Crist Quarry just to the east of Bugsworth. The 'stick' element of the contract was the stipulation that, on average, the kilns must produce six boat loads of burnt lime per week (about 150 tons) otherwise the Canal Company was at liberty to give Hassall and Satterfield one month's notice to quit and charge a proportionate part of the rent due at the time of quitting.

There is no documentary evidence to confirm that Hassall and Satterfield did build two additional kilns and improve the existing three kilns but subsequent events showed that they must have met the terms of the contract. It is known that the Satterfield family worked the New Road kilns for many years afterwards, so neither were they delivered up to the Canal Company at the expiry of one year in good working condition, as stipulated in the contract.

By 1815 the demand for burnt lime had increased considerably and a warehouse on the north side of the Middle Basin at Bugsworth was demolished to allow construction of the Middle Basin Arm and lime shed. Archaeological evidence shows that two lime sheds were consecutively built at the head of this short arm. The first spanned half the width of the arm on its western side, which could only accommodate one boat. As more kilns were added to the battery in order to increase the output of burnt lime this was demolished and replaced by a second shed that spanned the full width of the arm and could accommodate two boats.

Available evidence suggests the following sequence for building the eight New Road Kilns:

Circa 1808: Work on building the first three kilns commenced. 1811-12: The fourth and fifth kilns were built. Derby Mercury, 2 Feb 1820: Freehold Estate at Bugsworth and Chinley to be sold by auction on Thursday, 2 Mar 1820 at 3 o'clock in the afternoon by Mr Breary at the house of Mr Thornhill, the King's Arms, Chapel-en-le-Frith. Lot 10: Lime Kiln Piece, in which are five Lime Kilns and a Stable for four horses. This Lot is now under Lease for 16 years, and will be sold subject to such Lease.

(By 1825: The sixth kiln had been built.) Derby Mercury, 12 Sep 1827: Freehold Estate at Bugsworth. Seven Lime Kilns and Cottages (the whole subject to a Mortgage of Thirteen thousand pounds) shall be sold or disposed of by Public Auction. Shortly after 1827: The eighth kilns was built.

The New Road Kilns were the most technologically advanced to be built at Bugsworth, particularly in that their height was greater and this improved the combustion of the coal and ensured that the burnt lime was cooler by the time it was withdrawn from the base of the kilns. These kilns were also lined with firebricks supplied by John Hall & Son of Dukinfield, Cheshire. This lining would improve the thermal efficiency and increase the intervals between shut downs for maintenance purposes.

The burnt lime was removed from draw tunnels at the base of the kilns and then taken by wheelbarrow across the diversion channel of the Black Brook. To ease the river crossing, three footbridges were provided, these being planks without safety rails.

Boat loading had to be done under the cover of a lime shed because it was essential to keep the burnt lime dry, as it would react strongly when it came into contact with water. Once a boat was fully loaded the lime was sheeted over with tarpaulin. Presumably, when the weather was inclement, the wheelbarrows were similarly sheeted over with tarpaulin. Wet burnt lime was said to have 'fallen' and it was unsaleable.

At first, limestone was brought to the head of the kilns on a single-track tramway branch that crossed the diversion channel of the Black Brook on a stone-built bridge adjoining the north-east corner of the Navigation Inn. After crossing Brookside on a level crossing there was a turnout (points) that led down an incline to the foot of the kilns. This made it possible to remove ash from the kilns for disposal in and around the village. It could also be used to remove any burnt lime that happened to be sold locally.

Additionally, it was also used to carry incompletely burnt lumps of limestone back to the top. Workers known as Lime Pickers did this and the incline became known as the Bullhead Road because of its proximity to the Bull's Head Inn at the centre of Bugsworth. It appears that the lumps of incompletely burnt limestone were known as 'Bullheads' (pronounced 'Bull'yeads' in local dialect). There are three known possibilities for further processing of this:

The lumps were put back into the top of kilns for re-burning. They were broken up with sledge hammers for use in road repairing. Latterly, they were taken to the limestone crusher house in the basin and crushed for use as railway ballast or even road making.

Coal to fire the kilns was supplied from Lady Pit (to the NNW at Gowhole), Bugsworth Hall Pit and Dolly Pit (to the north at Clough Head). In order to facilitate the supply of coal from Dolly Pit it was connected to the head of the kilns by a single-track tramway running down the hillside. It is feasible that coal from Lady Pit was transported on this tramway after being carted to the head of the tramway but there is no evidence for this. Coal from Bugsworth Hall Pit was similarly transported. Bugsworth Hall Pit was closed in 1865 by the Midland Railway Company when they constructed their new line. It is known that coal was boated into the basin from Whaley Bridge and New Mills and possibly from even further afield. Whether any of this was ever taken to the kiln heads via the three footbridges and then up the incline is unknown. Possibly a more convenient route was used for this purpose.

In the late 1860s, the original tramway branch used to convey limestone to these kilns was superseded by the new single-track Elevated Tramway Branch that left the main line near a footbridge over the Black Brook. Its overall length was about 720 yards and initially it ran parallel to the tramway main line along the top of a stone-faced causeway some 230-yards long. It then crossed the medieval packhorse route (between Macclesfield and Glossop) and the Black Brook on two stone-built skew bridges. After crossing the Black Brook the branch turned away from the tramway main line and crossed Brookside in Bugsworth on a level crossing where there was a small stone-built weigh house used to weigh the limestone being delivered to the lime kilns.

From the early 1800s until the late 1860s the Satterfield family dominated the occupancy of these kilns. This was a wealthy family of merchants with offices at 1 London Road, Piccadilly, Manchester, and the Manchester and Salford Trade Directories between 1804 and 1858 list the following:

Joseph Satterfield Satterfield and Barnsley Satterfield and Hassall Satterfield and Cresswell Satterfield and Company Robert Satterfield and Company Mary Satterfield (sister of Robert Satterfield)

Derby Mercury, 16 Jun 1830: Further particulars about the Sale or Let on Lease of a Cotton Mill, Steam Engine and Farm situate at Bugsworth can be obtained from Messrs. SATTERFIELD and CRESSWELL, Piccadilly, Manchester.

In 1843, the Minute Book of the Peak Forest Canal Company mentions Satterfield and Clayton.

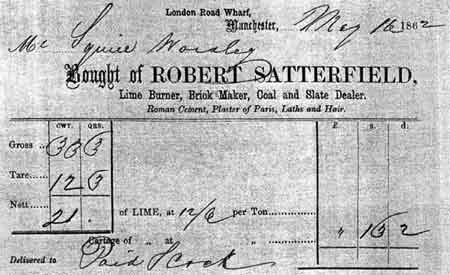

Lime Bill issued by Robert Satterfield

The above bill, dated 16 May 1862, is for the sale of 21 cwt of lime from London Road Wharf, Manchester, sold to Squire Worsley and receipted by Robert Satterfield's clerk, S Cock.

By 1870 the New Road Kilns were under the occupancy of William Pitt Dixon, a wealthy Derbyshire merchant, and he was still there in 1891 when he merged with the newly incorporated Buxton Lime Firms Company Ltd (BLF). Although he was not to know it, this merger was significant in the development of the chemical industry in the United Kingdom. In 1916, Brunner Mond of Northwich, Cheshire, acquired a controlling interest in BLF and Brunner Mond became part of Imperial Chemical Industries (ICI) on its formation in 1927.

There are no records that show the sequence of closure of the New Road Kilns but by 1921 it is understood that only five or six of them were still workable but non-operational. In 1909 it was reported that the imminent closure of the remaining working kilns was under consideration but nothing came of this. The received wisdom is that the last working kilns probably closed sometime during the period of the Great War (1914-18). However, at the time of abandonment it is known that one of them had just been refurbished and filled ready for lighting.

Bugsworth resident, Mrs Martha Barnes, recorded in her memoirs that towards the end of their working lives only two of the eight New Road Kilns were burning full time with a third kiln on standby ready to be lit should a big order be received.

Subsequently, much of the stone facing the front of the kilns was robbed for building purposes. The condition of the kiln pots and draw tunnels is unknown.

References to lime kilns from the Minute Books of the Peak Forest Canal Company

27 Jul 1825, no Minute number

···· six valuable LIMEKILNS in full business, with cottage and land thereto belonging, in the occupation of Messrs. Satterfield and Cresswell, containing 2 acres 2 roods 34 square poles (2.713 acres) ···· were sold by auction.

The above reference specifically concerns the New Road Kilns.

19/20 Jun 1833, no Minute number

Mr. Wood ordered to make a section from the splicing to Satterfield's Kilns over the Kilns on to the Wharf near the New Shed also one past the end of the Kilns and between the Kilns and the Bridge on to the same Wharf with a view to make more Pens for increasing Trade in Limestone.

The above reference specifically concerns the New Road Kilns.

John Wood was the Engineer to the Ashton and Peak Forest Canal Companies.

This Minute concerns the undertaking of a survey of the area of the kilns with a view to constructing additional pens for the storage of limestone. The 'splicing' refers to the turnout (points) in the original tramway branch on the approach to the kilns. One turning led to the kiln heads for the delivery of limestone and the other led down the incline to the foot of the kilns. Presumably there was a bottleneck in the storage of limestone prior to it being burnt in the kilns.

The 'New Shed' refers to the enlarged lime shed that replaced the earlier shed. The 'Bridge' is the stone-built bridge that takes Brookside over the Black Brook.

9 Aug 1839, no Minute number

Meadows with Wood directed to take an early opportunity of proceeding to Newcastle-upon-Tyne to examine the Kilns there and to ascertain whether any improvements can be made in the Plan of the kilns to be erected by this Company.

'Meadows' was James Meadows Junior and he was the Joint Principal Agent of the Ashton and Peak Forest Canal Companies. The Canal Company was at the height of its prosperity and was devising plans to expand lime burning at Bugsworth. It obviously wished to have the most modern type of kilns then available.

6 Apr 1843, Minute 2

Meadows was directed to have plans prepared of four Kilns to be forthwith erected at Bugsworth.

The Canal Company seems to have procrastinated since 1839 over the issue of erecting new kilns at Bugsworth.

20 Apr 1843, Minute 3

A discussion took place relative to the building of more Kilns it being stated that if additional Kilns were erected parties might be induced to embark in the Lime Trade and by means of more competition greater quantity of Lime would be brought down the Canal.

Resolved, that the sub-Committee have the power of erecting three or four Kilns upon such construction and in such situation as they may think best.

Later in the month of Apr 1843 it seems that the Committee had, at long last, recognised that it had dithered far too long over this issue and so it got rid of it by passing it to a sub-Committee to deal with. Moreover, it no longer cared where the kilns were built, leaving responsibility for this to the sub-Committee.

By 1843, the Committee must have realised that their limestone and lime carrying business was soon to go into decline because competition from railways now posed a real threat. On the 5 May 1837, the Sheffield, Ashton-under-Lyne and Manchester Railway Company was incorporated and their railway opened on the 17 Nov 1841. In the event, the Ashton, Peak Forest and Macclesfield Canals were leased to the Sheffield, Ashton-under-Lyne and Manchester Railway Company on the 25 Mar 1846. On the 1 Jan 1847 this railway company merged with other companies to form the Manchester, Sheffield and Lincolnshire Railway Company. As it happened, no more kilns were built anywhere along the Ashton and Peak Forest Canals after they had been leased to the railway company.