The above report suggests that there were two inclined planes. The lower incline was used to remove coal from the coal face in the Black Mine and transport it to the bottom of the engine brow (inclined plane) and when the coal had been winched up this it was at the pit bottom, that is, at the bottom of the winding shaft.

At just after 9:00am on the 18 Jan 1889 there was an explosion at Hyde Lane Colliery that resulted in fatalities. The toll was 23 men and boys with another five seriously injured.

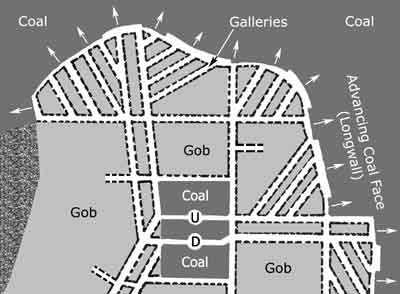

Longwall Method of Coal Working

With reference to the simplified plan of a coal mine shown blow, the upcast shaft (stale air drawn out) and downcast shaft (fresh air drawn in) are shown in the centre, marked U and D respectively, and

these are surrounded by uncut coal. The downcast shaft is also the winding shaft. Galleries radiate from the shafts and the roofs of these are supported by pit props. The grey areas have been shut (abandoned) and

these are the 'gobs'*. Here, all the coal has been removed and the roof is allowed to settle down gradually. In the 19th century, each coal face or wall was about 100 yards long and this is where coal was

being hewed and then carried to the surface. As the coal was removed, waste stone was used to build drystone walls that were typically from 6 to 20 feet wide and these were arranged in parallel lines at right angles to the

advancing coal face or wall. The purpose of these was to support the roof after the coal had been removed. As the coal face advanced, the underground railway system for carrying coal away was constantly being rearranged and

increased in length.

*Depending upon the district, the words 'gob' and 'goaf' can both refer to the same thing, namely the void left after coal has been extracted. The word 'gob' can also refer to waste material separated underground.

U = upcast shaft (stale air drawn out)

D = downcast shaft (fresh air drawn in)

Circulation of fresh air underground was controlled by a system of doors and ducts that are not shown for clarity.

A disadvantage of longwall working was that more gas could be released from a coal seam depending upon its volatility. When the gas released was firedamp (maimly methane) then there was an increased risk of an explosion. Following such an explosion, a toxic mixture of gases known as afterdamp could be left. This consists of carbon dioxide, carbon monoxide and nitrogen. Additionally, hydrogen sulphide, a highly toxic gas, could also be present. Nevertheless, it is usually the high content of carbon monoxide which is fatal by depriving victims of oxygen by combining with haemoglobin in the blood. Afterdamp was the lethal gas which caused many casualties in the pit disasters of the British coalfields. Another gas was blackdamp (stythe or choke damp) which is an asphyxiant that reduces the oxygen content of air to a level incapable of supporting life. It is not a single gas but a mixture of unbreathable gases left after oxygen is removed from the air and typically it consists of nitrogen, carbon dioxide and water vapour.

The suffix in the words firedamp, afterdamp and blackdamp derives from the old High German word 'damph' or 'dampf' which means 'vapour'.

Acknowledgement

Thanks are due to A Etchells.