These hatting objects represent materials, hand tools and personal items used by hatters, milliners and hat wearers.

Hat hoods were made of felt, a non-woven cloth, and they were created in a procedure called ‘planking’. After planking, the next stage was to form the hoods to the required shape on wooden hat blocks.

Hat blocks of the required shape were used to form hat hoods into hats.

William Plant & Sons of Great Ancoats Street, Manchester, was one of the last traditional hat block manufacturers and it closed in 1976.

The illustration on the right shows the underside of a hat block marked with the company's name and address.

The boomerang-shaped puller downer is held with two hands and it is used to pull the felt hood down tightly over a hat block.

To use the pusher downer a cord is temporarily tied around the crown of a felt hat and the pusher downer is then used to push this down to the point where the crown of the hat meets the brim. In so doing the corner between the crown and the brim is formed.

The foot tolliker is used to create a sharp corner between the crown and brim of a felt hat.

On the left is a hat steamer used in the blocking and forming of hats. Their purpose is to dampen and soften felt without affecting the stiffener in it or saturating it. During steaming a felt hood becomes pliable and easy to form into the required shape on a hat block.

On the right is a hat sewing machine and these are typically used to sew the hat bands and linings of hats.

On the left is a hat crown sad-iron and on the right is a hat brim sad-iron. The hat crown sad-iron has a curved ironing surface and it is used to smooth areas where the brim meets the body and other curved surfaces.

It is understood that sad-irons were so called because they were very heavy to use. Initially they were of all cast-iron construction (shown left) and the handles became very hot when the they were heated up for use.

The hat brim curling iron on the left is also known as a hat brim curling groove tolliker. The hat egg iron on the right is used to shape and smooth felt into hollow areas of a hat block such as one used to form trilby hats.

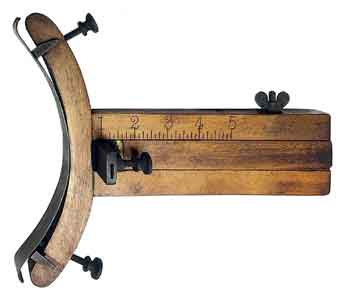

The boxwood hat-brim cutter is used to cut the brim to the required width measured from the crown of the hat. To use it, a hat is placed over a hat block resting on a cutting mat. While holding the hat down the curved part of the tool is held against the crown and then pressed down so that the cutting blade below the tool cuts through the brim. The tool is then rotated around the crown and the blade cuts the brim to the required width. Usually, a brim can be cut from one inch up to five inches wide.

The hat stretcher on the left consists of two 'C' shaped wooden slides connected by a turnbuckle that opens the slides. The stretcher on the right, also known as a hat jack, is also opened with a turnbuckle and it can be used either to retain the hat size or increase the size.

This hat block and stretcher is made in two halves, one fixed to the base and the other sliding on two wooden pins, with a metal adjusting screw to either wind apart or wind together the two halves.

The boxwood and brass hat size-rule on the left extends from 5 up to 9 inches and the reverse has a table of hat sizes, length and width measurements.

The hat-size callipers on the right were used to measure the size/circumference of the inside of the hat. The left-hand side of the tool is fixed to the spring-steel ring. The callipers are first closed and then released inside the hat so that the ring opens to form a close fit. The size can then read off on the brass scale.

The McDonald's rotary hat iron was patented in the USA in 1892 by Alexander McDonald. It was designed to smooth top hats and it was heated by gas.

The late Victorian era stand on the left is for hats, coats, walking sticks and umbrellas with a drip tray. The bentwood stand on the right is from the 1920s and it has six ‘S’ shaped scrolls for hats and coats joined to the top of a column supported by four down swept legs with two rings for walking sticks. Normally, stands like this would be placed in the hall.

Hat boxes left and centre date from the late Victorian era while the hat box on the right dates from the 1930s.

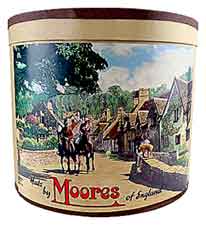

This customised cardboard hat box was supplied by J Moores & Sons Ltd of Denton, Lancashire, but it was made for them by a specialist company. Four local companies of hat-box makers were, William Platt of Heaton St, Denton; Robert Beswick, Peter Blyth, and Julius Downs & Sons, all of Hooley Hill, Audenshaw.

The origin of the Quaker hat dates back to the early 17th century and it is a wide brimmed hat with a low crown. This style of hat became popular again during the Victorian era and it was at this time that it acquired its second name of ‘wideawake hat'. This name came from the Wide Awakes, a youth movement associated with Abraham Lincoln in the USA.

Decorative hat pins were fashionable in the late Victorian and Edwardian eras as ladies used them as a means of attaching their hats to their hair. Their popularity reached a peak during the Edwardian era when ladies wore exceptionally large hats displaying colourful replicas of flowers, fruits, birds and whatsoever else could be made-up. Hat pins were sometimes sold in identical pairs and most were long (6 to 8 inches or more) because they needed to be long enough to reach through the hair.

Hat pin holders were made either of wood, metal or porcelain in a wide variety of designs. Some high-end hat pin boxes were made either of silver or with a cut crystal glass body and silver lid.

This millinery mould set was used was used for making flower shapes in fabric for decorating ladies’ hats or other items of clothing. The fabric was first dampened by a steamer to soften it without affecting the stiffener in it or saturating it. The fabric was then laid over the die ready for forming. The punch was then heated and used to press the fabric into the die to form the flower. Finally, the fabric was trimmed to the required size.

As an alternative to felt, hats began to be made from velour during the 20th century and its use became increasingly popular. Velour is a soft, plush fabric similar to velvet and velveteen. It is usually made from cotton but it can also be made from synthetic materials such as polyester or a blend of cotton and synthetic materials. It is used in a wide variety of applications, including clothing and upholstery. The soft texture on the surface of velour is known as ‘pile’ and is made by cutting across looped threads in a special weaving process.

Named after Lord Viscount Petersham (1780-1851), Petersham ribbon is used for hat trimmings, also known as galloons. It has a heavier weft than its warp which creates prominent transverse ribs. Significantly, it is woven with picot (scalloped) edges so that when it is steamed it will take on the required shape without forming wrinkles or puckers. Grosgrain ribbon is similar but it does not have picot edges so it does not have the same ability to follow curved surfaces.

Left, Walker, Ashworth & Linney Ltd of Ashton Rd, Denton, and right, Howlison & Co of the Tiviot Dale Hat Works, Heaton Norris, Stockport.

The term ‘Stelastic’ was a registered trademark for hats having a steel texture elastic fitting and they were introduced in c.1931 by hat manufacturers J Moores & Sons Ltd of Denton, Lancashire. They were light-weight hats with a comfortable fit.

Both hat models were introduced by J Moores & Sons Ltd of Denton, Lancashire. 'Tween' refers to a range of hats made in half sizes in the same way that boots were made in half sizes. 'Zephyrus' refers to a range of hats that were of imperceptible weight. Zephyrus is the ancient Greek god of the west wind or spring.

The label of the Felt Hatters & Trimmers Unions was introduced in Jan 1895 and it was fixed to the inside of the hat band. The two unions participating in this arrangement were the Amalgamated Society of Journeymen Felt Hatters (AJFH) and the Felt Hat Trimmers & Wool Formers Association (FHT & WF). At the foot of the label, the male hand on the left (AJFH) is shaking hands with the female hand on the right (FHT & WF).

Left, Walker, Ashworth & Linney Ltd and right, Joseph Wilson & Sons Ltd both of Denton, Lancashire, with London showrooms.

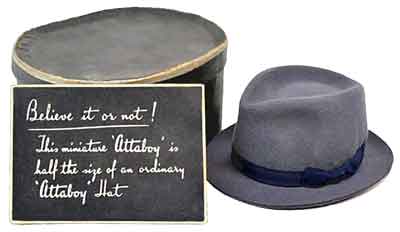

Printing block advertising the 'Attaboy' Nova hat. These checkered hats were made by the Denton Hat Co Ltd of Denton, Lancashire.

This miniature 'Attaboy' hat was made by the Denton Hat Co Ltd of Denton, Lancashire.

It is understood that one of the first hatters to make miniature hats was John Craig of Leeds who was making them by the early 20th century. Their purpose was to show the range of hats that he could make for both men and women and also the skills required to make them. Other hat manufacturers recognised the commercial benefits of making miniature hats and they too started to make them.

John Craig was born in Scotland in 1862/63 and he founded his business on Park Row, Leeds, in the late 19th century where he traded until 1936. Later trading addresses were Wellington St and Albion St, Leeds, and the business closed in c.1947.

An opera hat is designed to be collapsible for use in enclosed venues, such as an opera house or theatre. It consists of black fabric stretched over a sprung steel frame. To snap the hat open it is held upside-down by the brim with one hand while smartly tapping the opposite brim on the other hand. It is closed by holding the hat right-side-up by the brim with one hand while pressing on top of the hat with the other hand. When closed, the hat can be conveniently stored under a seat or in its box in a wardrobe when not in use.

One of several similar advertisements for hats

endorsed by British hat manufacturers.

During and after the Second World War the hatting industry went into severe decline and the slogan, “If you want to get ahead, get a hat”, first came into use in 1948. In that year the Hatters’ Information Centre, with offices at Denton and London was opened. Thomas Alfred Moores, chairman of J Moores & Sons Ltd of Denton, and president of the British Felt Hat Manufacturers’ Federation, reported that men are no longer “hat conscious”. Consequently, this slogan began to be used by hat manufacturers in an effort to convince the hatless of the error of their ways.